Concrete Edge Built-on Advantages

Over 15 Years of Experience | Used in Commercial and Residential Sites | Free Consultation

Over 15 Years of ExperienceUsed in Commercial and Residential SitesFree Consultation

Benefit From Our Concrete Forming Products

EnergyEdge products offer a wide range of built-on advantages. Equip your foundation and slab-on-grade assembly projects with our state-of-the-art products. Contact

our team of highly experienced professionals to know more.

Our Built-On Advantages Making Building Easier

When we talk about "built-on" advantages, we're addressing the many construction materials, assemblies, finishes, and weeping systems that terminate and transition at your slab edges. These complexities are made more demanding by the physical and environmental exposure you get with "at-grade" detailing.

At EnergyEdge, we've learned how to meet our challenges and complete the goals of designers and developers.

(Here are various examples of building systems and finishes whose function and technical performance goals are complemented and completed when they are transitioned at their base with an EnergyEdge product.

Please note that where manufacturers' or organizations' names or materials are recognizable in these images, EnergyEdge does not claim responsibility for that particular product's performance. We are using them only as an example of how our system interfaces with that type of material.)

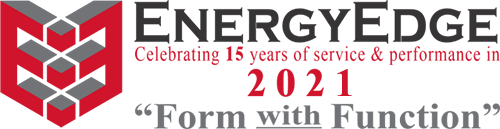

EIFS Industry and EIMA

Exterior Insulation & Finishing Systems (EIFS) has provided the construction industry with flexible solutions that both insulate and finish. EnergyEdge completes and complements the system's performance by providing a necessary weep offset, while also extending the exterior insulation value along the perimeter slab edge to grade below.

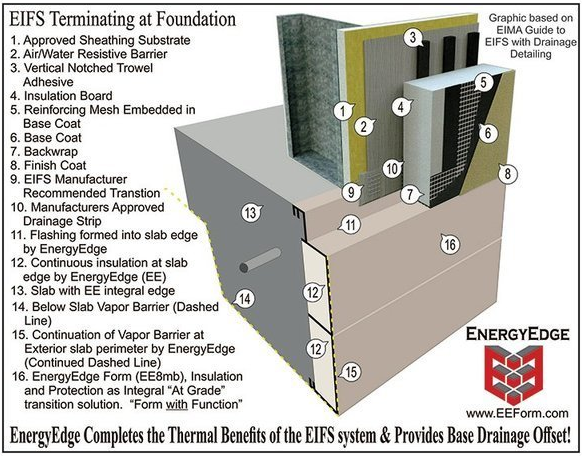

Insulated Sheathing Systems

Insulated sheathing systems, like those illustrated in this model, have become a valuable addition in raising the insulation value of walls and controlling their vapor and dew point performance. EnergyEdge insulated forming rails complement and advance the building's envelope by completing the performance of wall insulation systems at an otherwise “opened window” at the exposed slab edge.

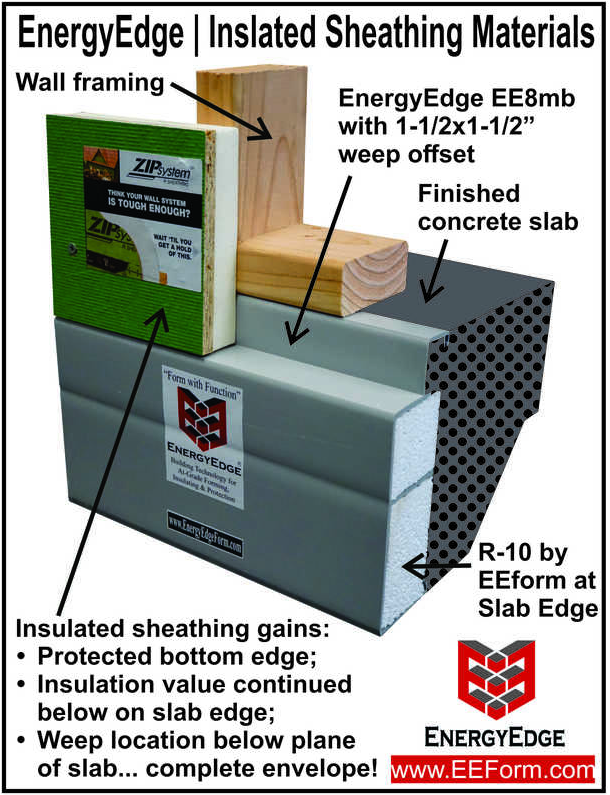

ICF Block Wall & Foundation Assemblies

ICF block foundation and basement walls require a protective transition from the backfilled edge to the finish material above. The “flashing” transition is simplified with the use of the EF214, EnergyFlash material. The EF214 flashing is installed in a “kerf” cut sliced into the perimeter wall approximately 8” above the projected finished grade. This is especially important in a basement wall application where the waterproofing material can extend above grade but is then protected by the EF214 flashing.

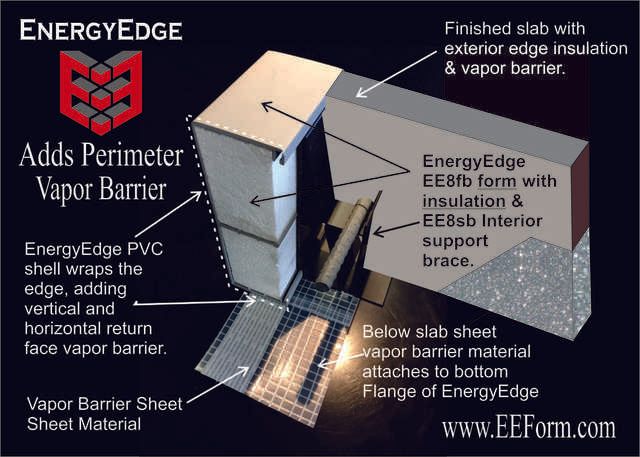

Below Slab Vapor Barriers

Below slab vapor barriers are necessary in most building environments. The extension of that barrier at the perimeter is difficult unless you are using EnergyEdge, stay-in-place, forms. Using a perimeter starter roll and attaching it to the bottom of the EErail creates a continuous link for the final placement of material before the slab pour. The assembly remains in place, with no stripping of forms required with EnergyEdge rails.

Share On: